A trip to Les Olivades is a vibrant dive into Provençal culture and craftsmanship! Located in Saint-Étienne-du-Grès, near Saint-Rémy-de-Provence, Les Olivades is one of only seven remaining ateliers producing traditional Provençal fabrics. These colorful, intricate textiles have been an essential part of the region’s identity for centuries, and a visit here lets you experience this rich tradition firsthand.

Originally, Les Olivades block printed fabric, which is a tedious, time consuming, labor intensive process. What is block printing? It’s just like it sounds. You literally take a block, dip one side in ink, and then put that block on the fabric to transfer the design. Block printing is really not done at all in France anymore. Most of the remaining block printers are in India.

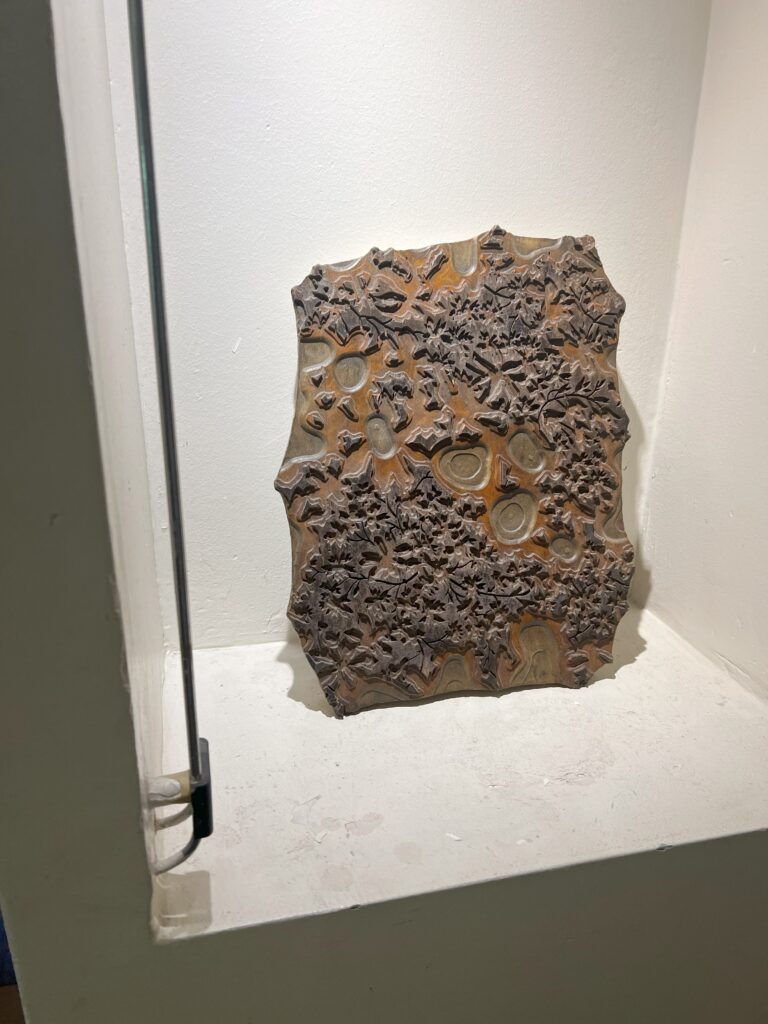

Here’s an example of a block print that’s still at Les Olivades:

So if they don’t block print anymore, what do they do? Les Olivades features three distinct printing methods: screen printing, roller printing, and digital printing.

Fabric Preparation

Not only do they print all the fabrics, Les Olivades also prepares the raw cotton or linen fabric for the printing process (no synthetics used here). The fabric arrives in giant 1400 meter rolls. It’s originally brown and rough. Les Olivades runs the fabric through a bleaching and drying process multiple times and then inspects the fabric before it even gets to the printing phase.

Here’s the inspection process:

Screen Printing

Watch artisans hand-print stunning fabrics using traditional techniques like screen printing. It’s fascinating to see how these timeless patterns come to life, combining old-world methods with modern flair. Nowadays, screen printing is done on LONG tables, where many repeats can be accomplished at once via a machine.

So, what do the screens look like? Here’s an example of one. (Yes, this is a Christian Dior fabric screen!)

The artisan creates and transferrs a design onto a mesh screen by blocking out areas of the screen using a stencil or light-sensitive emulsion. The areas not blocked allow ink to pass through. Then, the screen is stretched over a frame, and the mesh openings correspond to the design areas where ink will be applied to the fabric. Only one color can be used at a time, for one screen. If a fabric has multiple colors, every color needs its own screen.

Here’s what the ink buckets look like:

Once the screen is ready, the fabric is placed flat on a printing table or surface, and the screen is positioned above it. Ink is placed on the screen, and a squeegee is used to press and pull the ink across the screen, forcing it through the mesh onto the fabric in the open design areas.

The printed fabric is heat-set to ensure the ink adheres properly and is durable for wear and washing. This is a huge dryer:

This process is repeated with different colors and screens if the design involves multiple layers or colors.

Roller Printing

Roller printing, or cylinder printing, is a technique used to apply intricate patterns onto fabric efficiently. Introduced in the late 18th century, it uses engraved metal rollers to transfer dye onto fabric in a continuous process. Each roller corresponds to a different color, allowing multi-colored designs to be printed quickly and precisely.

This method is ideal for large-scale production, offering high-speed output and sharp, consistent patterns. While digital printing is gaining popularity, roller printing remains valuable for its precision and efficiency, especially for traditional designs and long production runs.

Digital Printing

The most modern technique at Les Olivades, digital printing has gained popularity in recent years due to its precision and cost savings over more manual techniques. These digital printers work just like a regular paper printer, or on a way larger scale!

One advantage to digital printing is the speed with which the fabric can be printed, using multiple colors of ink at one time.

Museum and Showroom

Not only did we get a tour of how the factory works – we also got to explore the on-site museum, which tells the history of Provençal fabric making. We also browsed the showroom filled with gorgeous tablecloths, linens, scarves, and more.

Whether it’s a vibrant scarf, a beautifully patterned tablecloth, or fabric by the meter, everything here bursts with the charm and beauty of the region. Everything here was of course roller or screen printed, the old school way, on wonderfully high quality linen or cotton.

Future Vision

While digital printing and cheap fabrics have revolutionized the industry, there will always be a place for high quality, artisanal products. The fabri manufacturers who work with Les Olivades continue to create new, exciting patterns every season. Here’s a sneak peek at some upcoming designs:

A visit to Les Olivades isn’t just about shopping; it’s a lively, hands-on journey into Provence’s artistic soul. And with its idyllic location near Saint-Rémy and the stunning Alpilles mountains, it’s the perfect way to immerse yourself in the local culture!

Ready to tackle some design? Contact us to chat about your vision!